How Sheroz Earthworks can Save You Time, Stress, and Money.

How Sheroz Earthworks can Save You Time, Stress, and Money.

Blog Article

Getting My Sheroz Earthworks To Work

Table of ContentsSheroz Earthworks - TruthsFascination About Sheroz EarthworksSheroz Earthworks - QuestionsGetting My Sheroz Earthworks To WorkThe 10-Minute Rule for Sheroz EarthworksFacts About Sheroz Earthworks Uncovered

Today, Smart Construction Remote connects over 700 equipments on jobsites to workplaces, saving thousands of hours formerly spent by jobsite managers, property surveyors and engineers travelling from workplaces to jobsites. To summarise, the initial 10 years of Komatsu's intelligent equipment control have been noted by a decade of unique advancement, consistent learning and advancement with customers.

Below's to the following 10 years! Material produced in association with Komatsu.

In the rapidly evolving globe of building and construction, accuracy and effectiveness are important. 3D device control, a system that uses general practitioner and various other sensors to guide equipment with identify accuracy, is changing the market - https://www.abnewswire.com/companyname/sheroz.com.au_142204.html#detail-tab. From its early days of 2D advice, this technology has actually advanced considerably, making jobs that when called for manual intervention now feasible with marginal human input

At the core of any kind of 3D device control system are GNSS receivers and antennas, catching satellite signals to establish the machine's exact place. Onboard computer systems and control boxes procedure this information and connect with the machinery.

Excitement About Sheroz Earthworks

This includes setting up GNSS receivers, adjusting sensors, and configuring the maker control software program. Once established, the system is incorporated with existing machinery for real-time adjustments and assistance. The magic of 3D device control depends on its real-time data collection and handling. GNSS and other sensors constantly gather setting data, which is dealt with for mistakes to supply reliable and accurate support.

Customer interfaces supply real-time updates on the machine's placement and needed changes, making sure accurate control. In construction, 3D machine control is utilized for earthmoving, grading, paving, and excavation, making certain jobs are completed to exact requirements.

How Sheroz Earthworks can Save You Time, Stress, and Money.

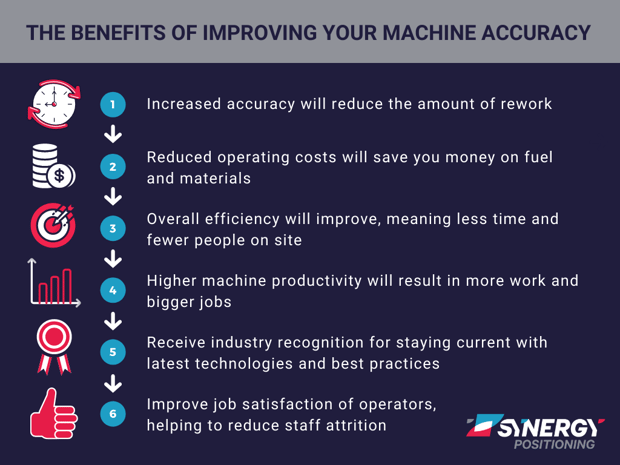

3D maker control substantially enhances efficiency by lowering rework and reducing material wastefulness, leading to faster and a lot more economical task completion. The innovation ensures every task is carried out precisely as planned, causing constantly top notch job. Among the most engaging advantages of 3D machine control is the considerable cost financial savings it offers.

Gas consumption is optimized because makers operate better and stay clear of unneeded activities. Upkeep expenses are additionally lowered, as the machinery experiences less wear and tear because of specific procedure. Generally, these savings add to an extra rewarding profits for any job. By reducing human error and restricting exposure to hazardous environments, 3D maker control improves employee safety and lowers crashes.

From building to mining, this technology ensures jobs are implemented properly and safely, lowering expenses and improving end results. As advancements proceed, the possibility for 3D maker control to better enhance efficiency and safety and security expands. Embracing this innovation is crucial for market professionals seeking to remain affordable and attain the highest standards in their projects.

The Main Principles Of Sheroz Earthworks

Discover the future of accuracy and effectiveness now! Additionally, have a look at our latest YouTube video clip on the FJD H36 Electric Motor Control System to see the modern technology in activity: See currently.

For many years, we've seen drivers with great deals of experience do some remarkable points with their machines. Perhaps they have an eye for changes that boost accuracy, or possibly they understand which functions of their device to utilize and when to improve efficiency or efficiency - https://myspace.com/sherozau. With today's developments in heavy tools technology, even competent operators can benefit from a real-time assist to improve their daily performance.

This is where equipment control systems aspect in. Some excavators come with equipment control systems that assist the operator with features to automate the digging procedure.

The 8-Minute Rule for Sheroz Earthworks

With this included accuracy, rework is virtually gotten rid of, enabling the operator to complete the project on time and transfer to the following task. For those dealing with dangerous or tough jobsites, remote-controlled options open new opportunities. This remarkable add-on permits you to run an excavator from a range in areas with hazardous substances (like in a potash mine) or bad ground conditions (like mud).

Maker control systems offer useful advantages to more than simply excavator operators. If you have actually a vehicle come in with a target of 23 loads, your driver can load their bucket and dynamically weigh itoften without also being fixed.

This indicates the operator can see the precise weight of the load they're about to dump (topcon laser levels). On-board evaluating provides real-time insight into the pail's load to make overloading, underloading, reweighing and waiting times a thing of the past. Volvo Building and construction EquipmentIf they dump 12 tons on the very first pass, the following container needs to consider 11 tons

Not known Facts About Sheroz Earthworks

A lot of procedures make use of an on-board weighing app to make sure that the tons is precise before they send their vehicles to the ranges, which is very important because the scale weight is what's utilized for billing and invoicing objectives. A number of producers consist of some kind of evaluating program on their loaders. Some additionally Our site have features that allow business to keep track of and manage the total lots of multiple trucks.

Report this page